Preventive

control of everything

Requirements and needs

are constantly changing.

As such, retrofitting might not just be the sensible option, but a necessary one. It is up to you to decide whether the retrofit concerns the core of a roll forming line – the roll forming tool – or whether a new or additional separating unit is required. A general line extension or the integration of a technical innovation is always helpful in pursuing the goal of achieving efficient and future-proof production.

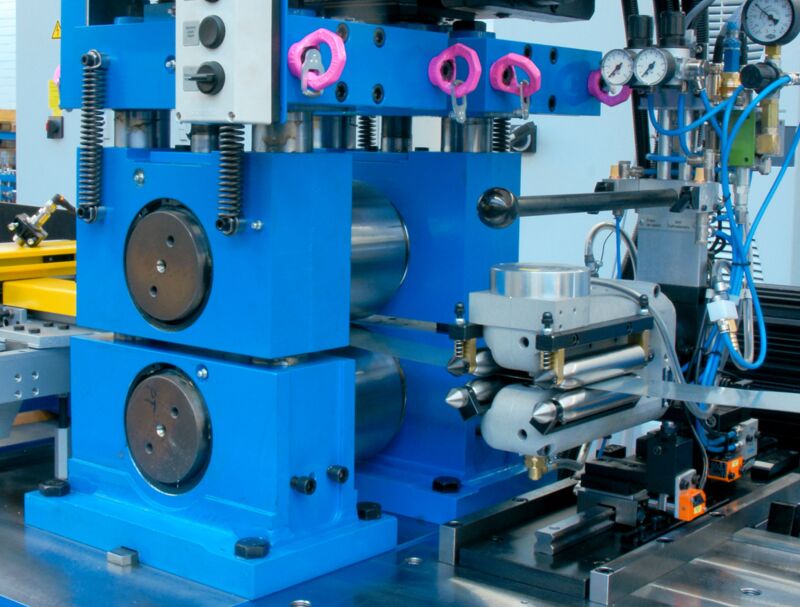

Roll forming line tools

You need perfect roll forming line tools to produce perfect products. That is why we test our rolls on a testing machine in our factory and supply sample parts for your approval. This helps to ensure a smooth commissioning of the machinery at your end. We can also manage the initial assembly and start-up of the tool at your plant.

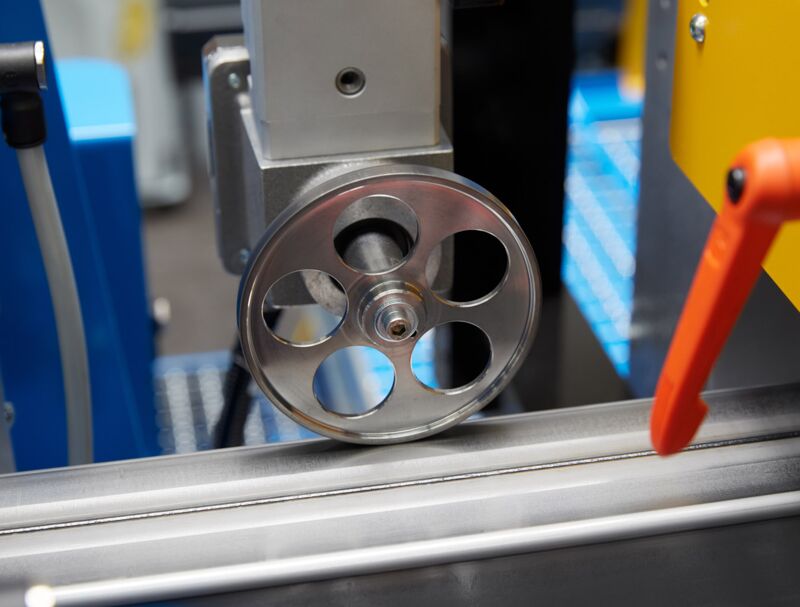

Plant extensions

Not possible? Never! By extending an existing roll forming line, you can produce new profiles or increase productivity as a whole. The main approaches for this are to extend the machine base so more forming stations can be integrated, or to add a synchronously running separating unit so that you can also manufacture in start-stop operation. A handling system, perhaps a cross conveyor for profiles, can also open up new profitable channels.

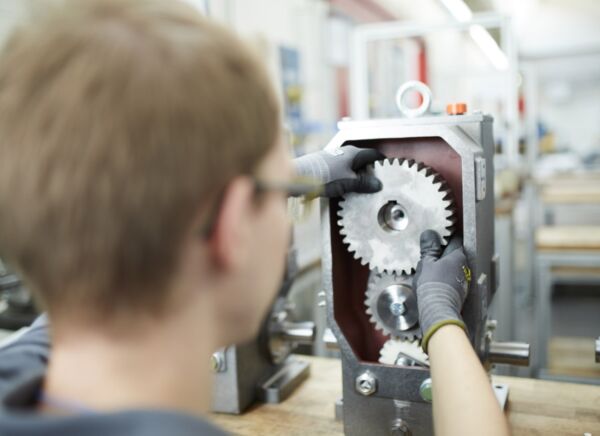

Integrating technical innovations

Technical progress is not an end in itself. However we can use sophisticated new products to improve your processes and your market position. One example of a turnkey solution provided from just one source is the retrofitting of your plant with multi-purpose units. These can, for example, be used as punching units and placed wherever they are required.