Our experts have extensive process know-how

in respect of trendsetting products

In some projects, we work together with competent partners: Together we have developed extensive process know-how, which we can exploit in the planning and implementation of innovative profiles.

New developments lower costs

Our roll forming experts are constantly setting new benchmarks in many areas with new developments, with which, amongst other things, you will benefit from improved process reliability and lower costs

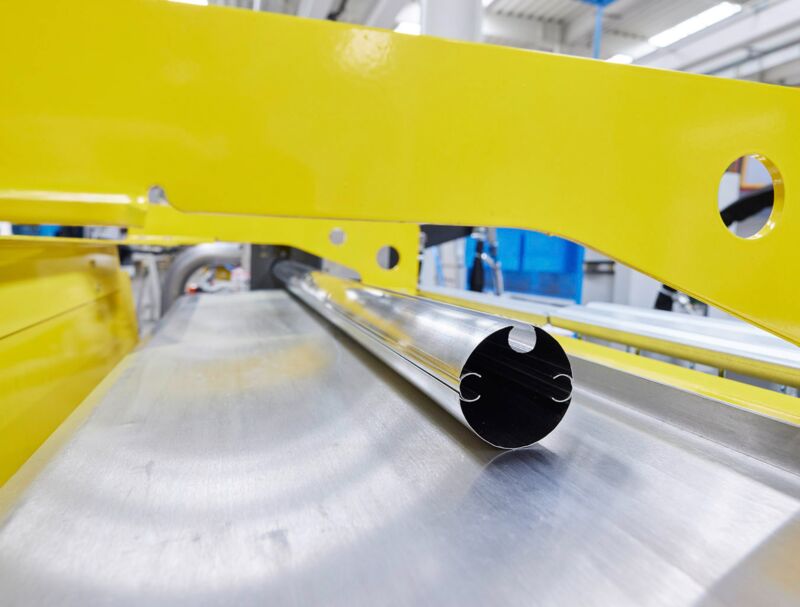

Good examples of the work of our roll forming experts include the fast and permanent connection of plastics to metals for the production of multilayer composite pipes, the foam filling of extremely thin-walled profiles with PU foam in the production line for the production of shutter slats or the Start-Stop laser welding of continuous welding seams in Start-Stop systems. This know-how is an important supplement is the implementation of innovative profile concepts.

Professional roll forming machines

clearly presented

Form your own impressions of the precision and reliability of our roll forming machines: The video shows you clearly some of the advantages of our roll forming systems and processes.