Brass or gold, copper or titanium –

there is no material that cannot be used

The correct basis for successful end products.

High and ultra-high strength steel grades, aluminium alloys or other materials such as copper, titanium, brass or gold: there is almost no formable material that has not already been processed into a successful product on one of our roll forming machines. Our engineers will advise you on product design and selection of the most appropriate material to achieve the required functionalities safely and economically.

Perfectly matched

to your requirement

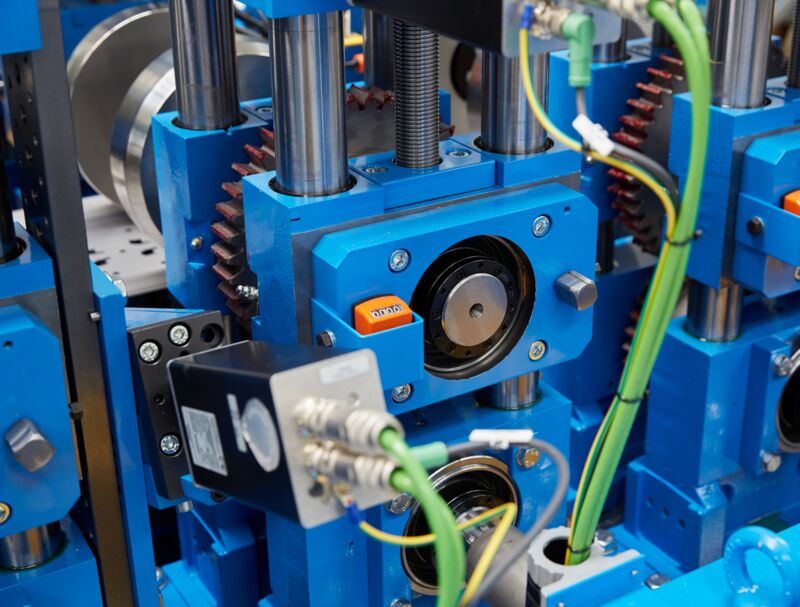

Our roll forming machines are optimally adjusted to cope with strongly fluctuating material properties, as for example those exhibited by high-strength steels: our special adjustment devices respond quickly and safely to such fluctuations. This gives you, for example, considerable advantages in the production of profiles for lightweight automotive construction.

Just as varied as the materials processed by our roll forming machines are their surfaces: hot or cold rolled steels, galvanised, painted or powder coated – each surface has specific requirements for the forming process. One surface will result in severe tool wear, another is extremely easily damaged. We realise solutions for you with which, for example, the roll coating optimally limits your wear or with which the forming is configured in such a way that damage to a sensitive paint finish is prevented.