Even under high pressure,

still in top shape

Protective pipes for fibre optic cable, tubes for medical technology, gas compensators for EGR heat exchangers for exhaust gas cooling – pipe welding systems for thin walled pipes are used in multiple applications. They are nearly always extremely difficult to produce: The thin-walled pipes produced using our roll forming systems do not buckle, even under high pressure.

A keen eye on your challenge

We take “thin-walled” to mean 80 µm as an absolute minimum with a diameter to thickness ratio of over 250. It is here in pipe production that "the wheat is separated from the chaff". Any error in the forming process, lack of precision in the individual machine components or selection of the incorrect welding process can have expensive consequences. Thanks to their experience from many supplied systems our roll forming experts have a keen eye when it comes to assessing a very wide range of project remits.

Examples of welding

thin-walled pipes

The supreme discipline in the production of thin-walled pipes on our roll forming machines is, among other things, the achievement of the desired weld seam.

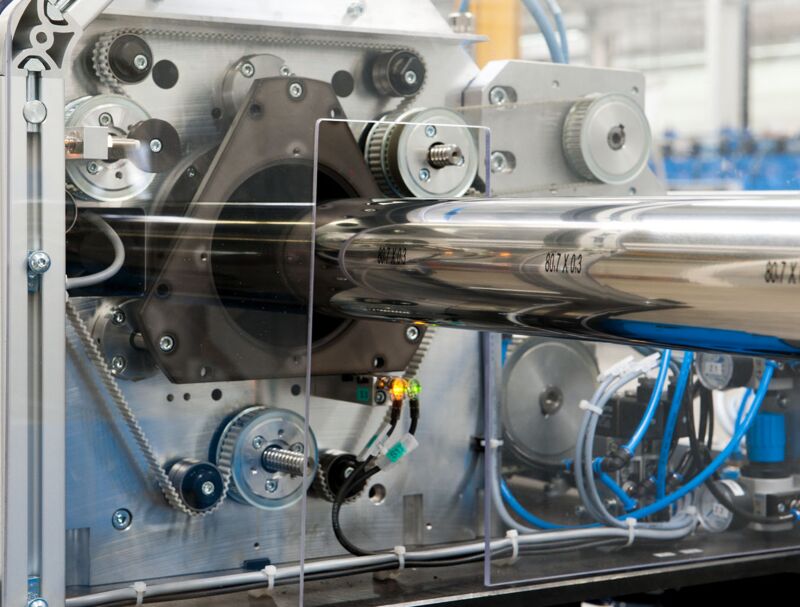

Thin walled laser welding system starting at 0,1 mm wall thickness

When a customer compares a laser welding system with a water tap, then at first sight, it does not appear to be a complement, nevertheless, that was how one of customers explained it when they wanted to say how easy and reliable it is to operate their system. Switch on and the pipe flows like water out of the tap – simple, reliable and always with the same high quality.

Laser welding system for fibre optic cable

Ten kilometres of fault-free welding is the requirement, if you want to be approved to produce fibre optic cables. Using our roll forming systems, you will fulfil the requirements and moreover produce more quickly than other companies. This is true even for the smallest pipe that can be produced using our roll forming systems without reducing. It has a diameter of just 1.7 millimetres.

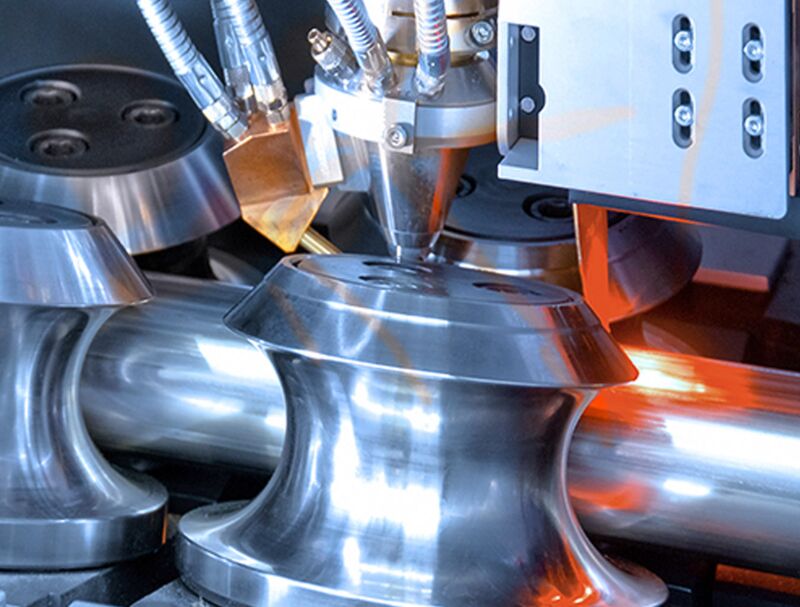

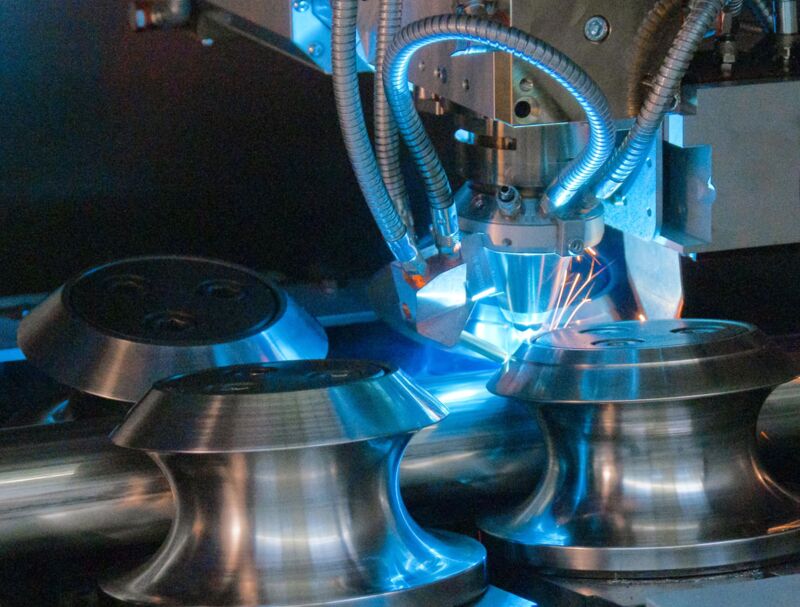

Laser welding systems for EGR exhaust gas heat exchangers

EGR exhaust gas heat exchanger operate in extreme conditions: Up to 100 kW heat load in the smallest of spaces, extreme temperature fluctuations with peaks of up to 900ºC and heavy mechanical loads are typical operating conditions. This places high demands on the heat exchanger pipes and on the necessary production technology: These are reliably manufactured on our roll forming machines.

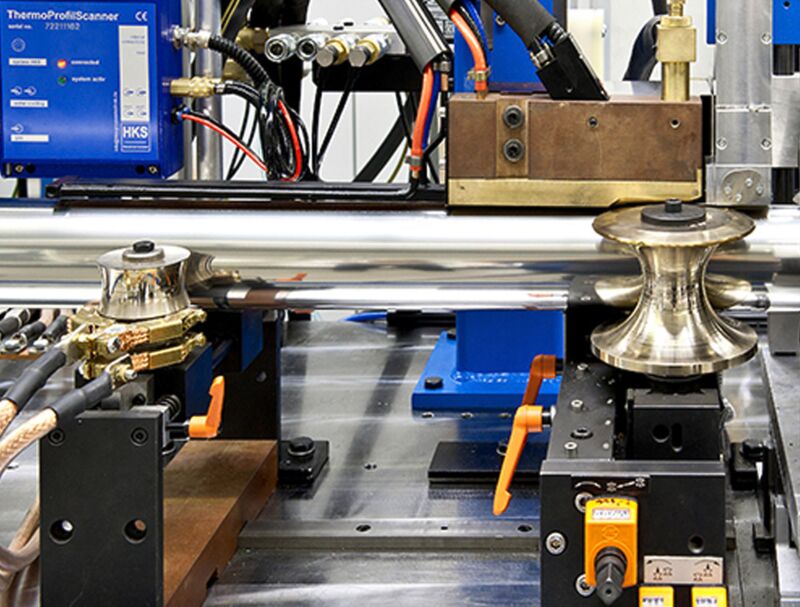

TIG welding system for compensator pipes

The production of compensators is a severe test on the quality of a welded joint: there is hardly any other application where the weld must withstand such high loads. However, that is not the only challenge in a production plant for compensator pipes: high production speed, fast dimension changeover and minimal scrap rates are additional challenges. Our roll forming machines fulfil all these conditions as well as ensuring economic production.