Fulfil the most demanding requirements

precisely and efficiently

Roll forming processes are established as efficient work steps for the production of ready-to-install lightweight parts for front and side impact protection. For example, with our custom-developed roll forming machines for front and side impact protection, you benefit from very economical processing of ultra-high-strength steels.

High productivity

roll forming systems

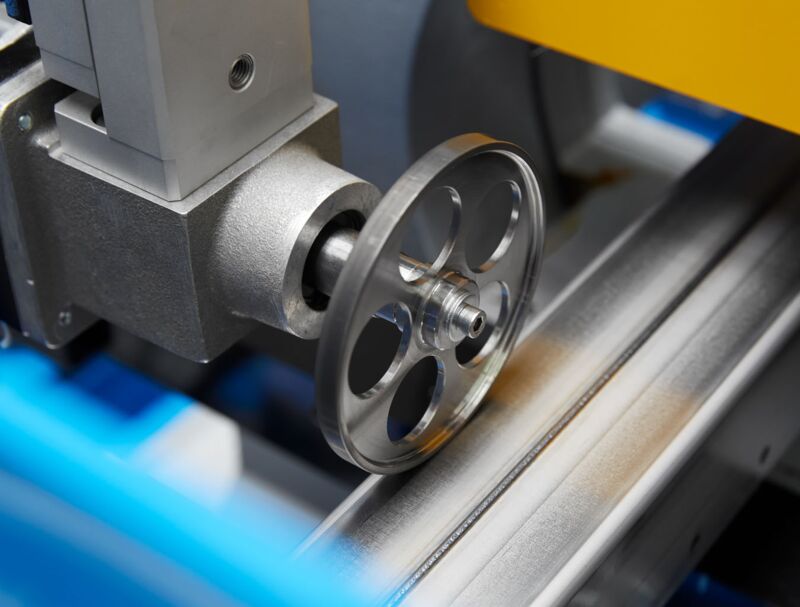

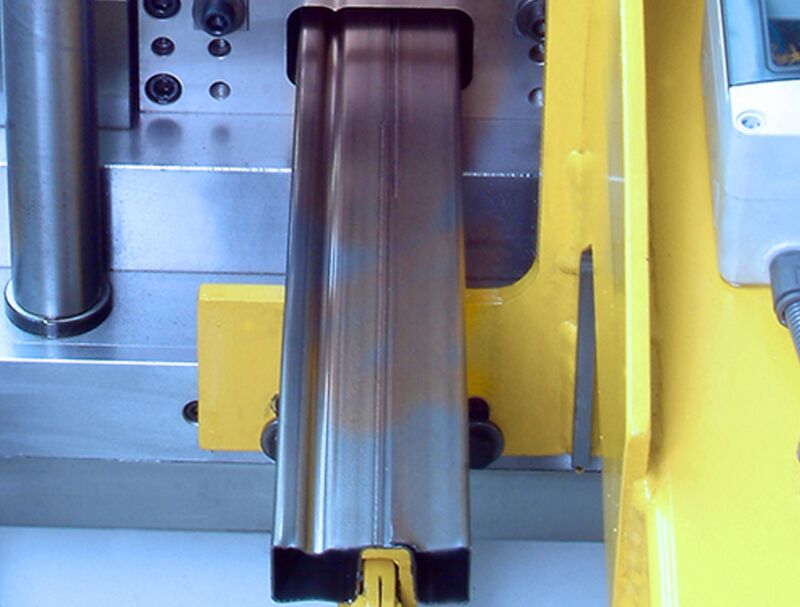

Due to the high stiffness requirements for front and side impact protection profiles, they are designed as welded hollow profiles. Laser welding or spot welding is used dependent on your particular conditions and the relevant cross-section. Our roll forming processes provide ideal conditions for good and fast welding: The achievable welding speeds of 8 to 15 metres per minute are well above the values that are otherwise usual in bodybuilding.

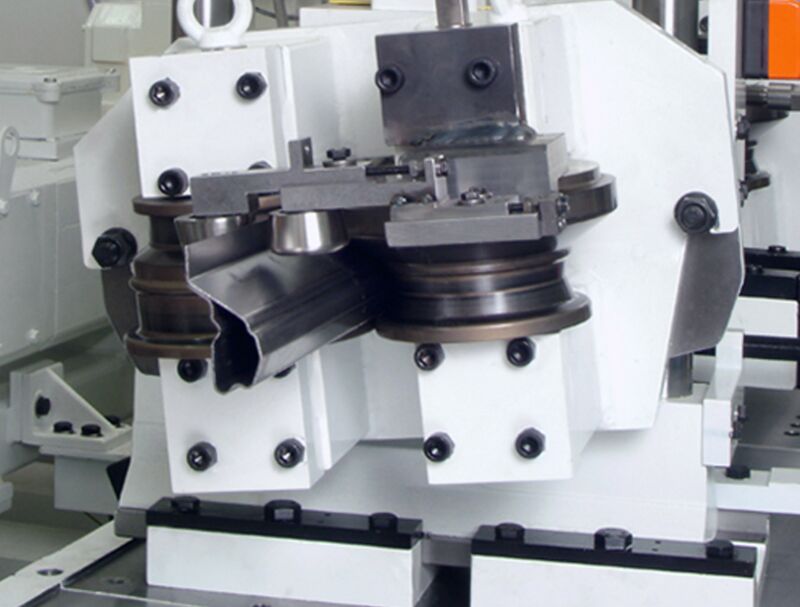

Front and side impact protection profiles are almost always curved along the longitudinal axis. Thanks to integrated bending equipment you can implement any required radii within defined limits. A change of the bending radius means solely a changed setting of the bending tool and has no associated tooling costs. Moreover right and left versions of the parts can be produced using the same roll forming tool, again requiring no extra tooling costs.

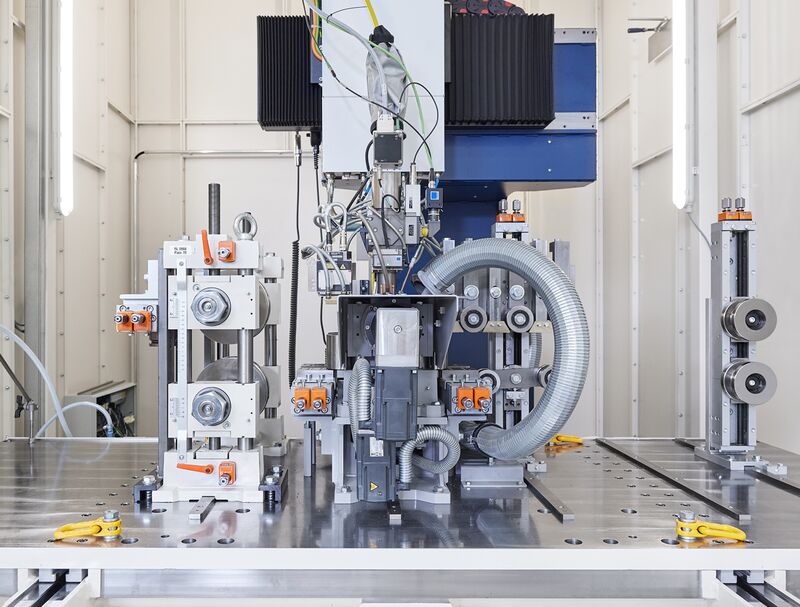

Frequently our highly productive roll forming systems are not used to capacity when producing a single product: Thanks to our flexible quick-change concept, you can therefore produce often very different components on our roll forming systems.

Professional roll forming machines

clearly presented

Form your own impressions of the precision and reliability of our roll forming machines: The video shows you clearly some of the advantages of our roll forming systems and processes.

Laser welded bumpers

Thanks to our many years of experience in the processing of ultra-high-strength materials, we have comprehensive knowledge in welding, bending and cutting to length. We adapt the forming technology closely to the material being processed. In addition, the choice of the correct laser type and suitable welding parameters as well as the optimal design of the separation technology are decisive: Using our roll forming machines you can fulfil these high requirements for safety parts.

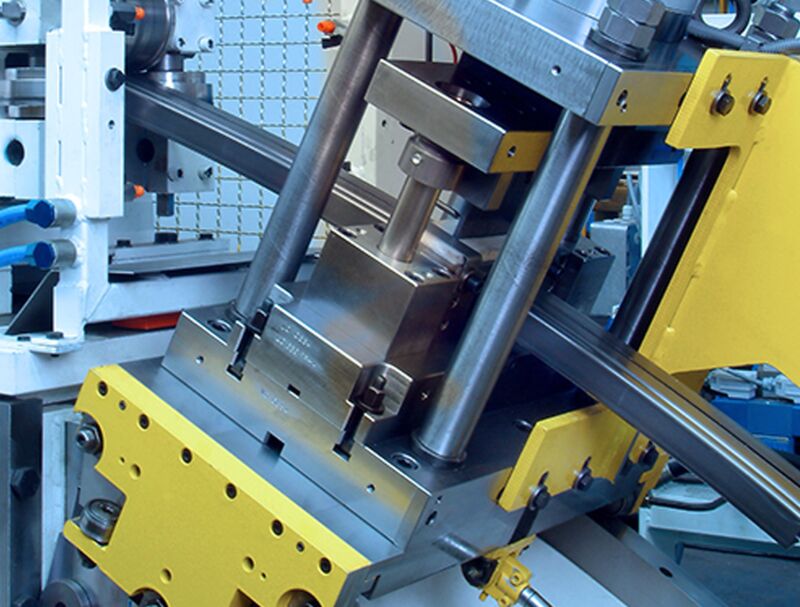

Window recess reinforcements and bumpers

One particular challenge are always the highly varying requirements for the punching technology. A short changeover time is also a requirement. Therefore our roll forming experts install a system part with the stamping technology for the bumpers on rails: it can be moved in out towards and from the line in a minimum amount of time. Through use of roll forming technology, there is no need for a weld flange. The result is a significant reduction in weight together with reducing direct costs.

Professional roll forming machines

clearly presented

Form your own impressions of the precision and reliability of our roll forming machines: The video shows you clearly some of the advantages of our roll forming systems and processes.

Spot welded window recess reinforcements

The investment costs for the spot-welding installation for this roll forming machine are less than 50 percent of the cost of a laser. With this roll forming machine, we have shown that spot welding is no slower than a laser approach. Use of rotating welding electrodes meant that a production speed of 12 metres per minute was achieved. Also noteworthy here is that our customer won the Swedish Steel Prize with this component.