Maximum dynamics

for successful processes

New technology concepts set particular standards in a range of industries. We are focussed on ensuring the success of your roll forming processes during every work step: which is why we are constantly developing new roll forming technologies for you that set exceptional standards in a very wide range of industries for a very wide range of roll formed products. This ensures you obtain roll forming machines with which you can produce your roll formed products with the required quality and quantity as well as with the targeted costs, thereby achieving a considerable competitive advantage.

- Roll forming

- Straightening

- Welding

- Punching

- Cutting-off

Roll forming

We can provide you with a comprehensive range of profile shapes. Here our roll forming machines achieve tolerances that just a few years ago would not have been possible. We place particular emphasis on low-strain forming: Your profiles produced in this way are notable for maximum precision and minimised cold work hardening. Moreover, your profiles remain formable to a high level, which is often a prerequisite for integration in your further process steps.

Straightening

Our various straightening processes are orientated with your individual requirements, with a particular focus on the materials you are using and the desired quantities of profiles. A few simple and fast processes, aimed at obtaining level parts, reduce your costs notably.

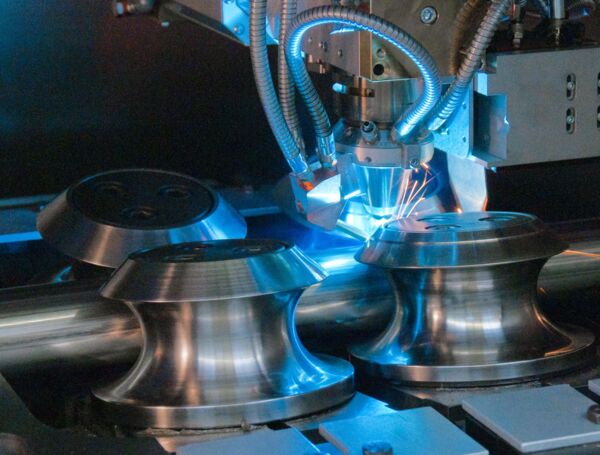

Welding

Welded pipes and profiles produced on our roll forming systems are notable for exceptional weld quality. This is because we take every detail into consideration, as for example the quality of the strip edges: clean without disruptive impurities, level and strain-free, perfectly aligned with each other with a precisely defined weld gap geometry.

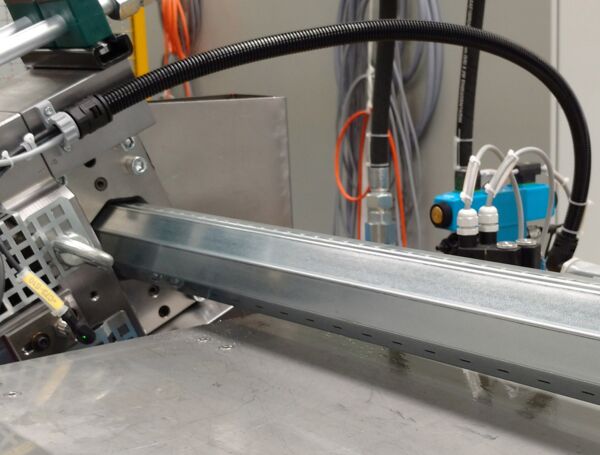

Punching

Our pre- and post-punching systems for assembly ready parts are configured for maximum production rates with maximum quality. You receive pre-punching systems in the form or rotary die cutters or flatbed die cutters with intelligent feed and tool technology for automatic setting up of pre-programmed hole patterns. For post-punching, we implement concepts to meet extreme flexibility requirements. In this way we achieve production rates of up to 120 parts per minute and changeover times of a few minutes.

Cutting-off

Our cut-off machines are suitable for various cutting-off processes such as sawing, shearing, punching or special processes. They are equipped with multiple details, including for example, adjustment options or profile or pipe clamping equipment. Consequently your costs per cut generally remain inside your calculated value.