From pioneer to trendsetter

for innovative and custom technologies

When we produced the first roll forming system for multilayer composite pipes in 1984, no one could envisage what unbelievable success this pipe would have: within just a few years, it became Europe’s favourite multilayer composite pipe for heating and mains water pipes.

Easy and quick laying

The success story of our pioneering work was based on the combination of the best properties of metal and plastics: The multilayer composite pipes have the temperature and pressure resistance of metal pipes combined with the corrosion-resistance of plastic pipes. They can be easily bent and retain their shape after bending. Therefore they can be quickly and easily laid. Using our roll forming systems, you can produce multilayer composite pipes with production rates of up to 60 metres per minute and with an extremely low scrap rate.

If you need to change the pipe dimensions, then our roll forming systems score due to their short changeover times: In a benchmarking test they demonstrated the shortest changeover times. Depending on your requirement, we will simply supply you with the roll forming system part for the production of the aluminium pipe or, alternatively, a turnkey complete system.

As a pioneer of composite technology, we continue to work constantly on further applications for composite pipe technology: In doing so, we have demonstrated that composite pipe systems can also process copper and stainless steel. For a thickness of just 80 µm, this opens up interesting new applications with persuasive cost benefits, especially for stainless steel composite pipes.

Examples of roll forming machines

for multilayer composite pipes

You benefit from our decades of experience when using our roll forming machines in the field of multilayer composite pipes.

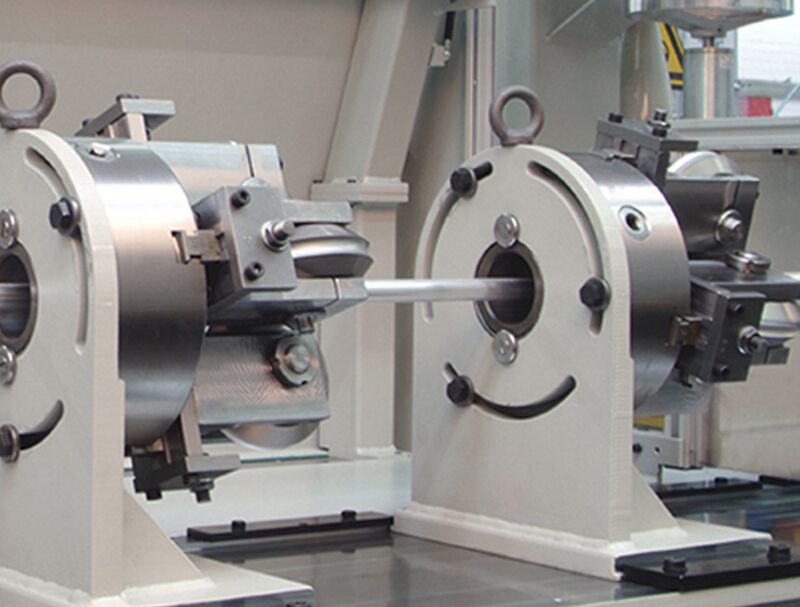

Strip feeding systems

Even more than so that in other scenarios, with pipe welding systems, the continuous supply of the strip feeding system with strip material is of high importance. Generally, composite pipe systems work for at least 5 x 24 hours per week, each shutdown results in laborious cleaning work on the extruders. We integrate strip feeding systems, which comprise two decoiling reels, one strip end welding machine and one strip accumulator. An important advantage of these strip feeding systems is that they can also process extremely thin-walled strips without any damage or over-extension. This is one of the prerequisites for fault-free welding and an extremely low scrap rate.

Trimming station

An oxide layer forms on aluminium in air; this layer must be removed prior to welding. This task is undertaken at the trimming station, which cuts off 1 – 2 millimetres from each end. Our trimming stations can be continuously and precisely adjusted to the correct strip width. They ensure perfect strip edges and the exact strip width for the pipe forming process. Together with the strip feeding system, this is the second prerequisite for fault-free welding and an extremely low scrap rate.

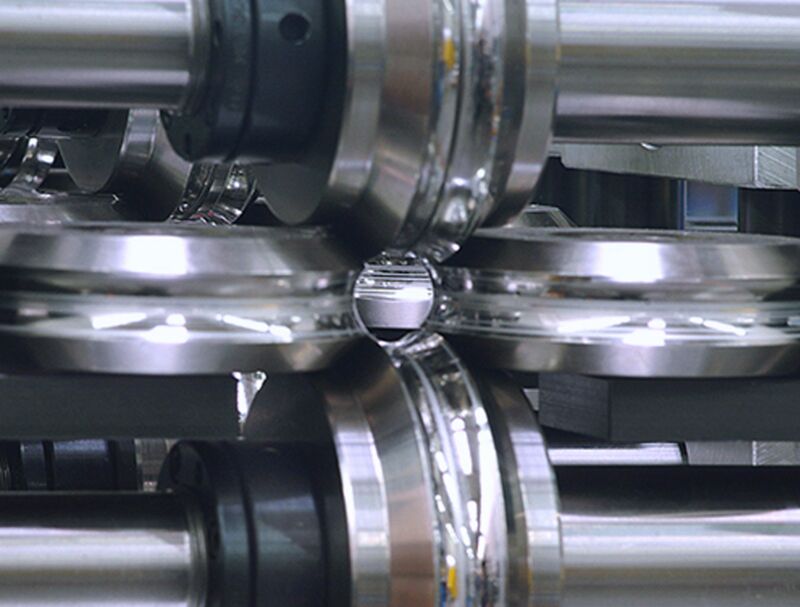

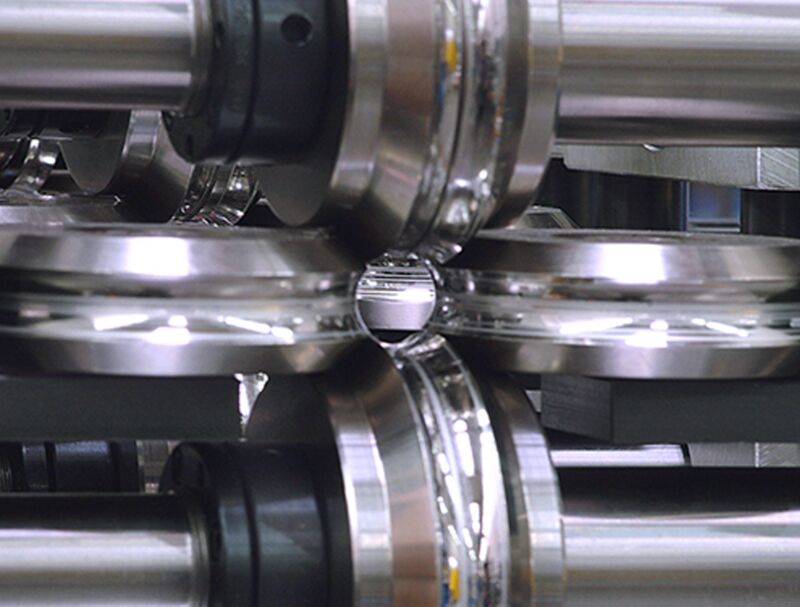

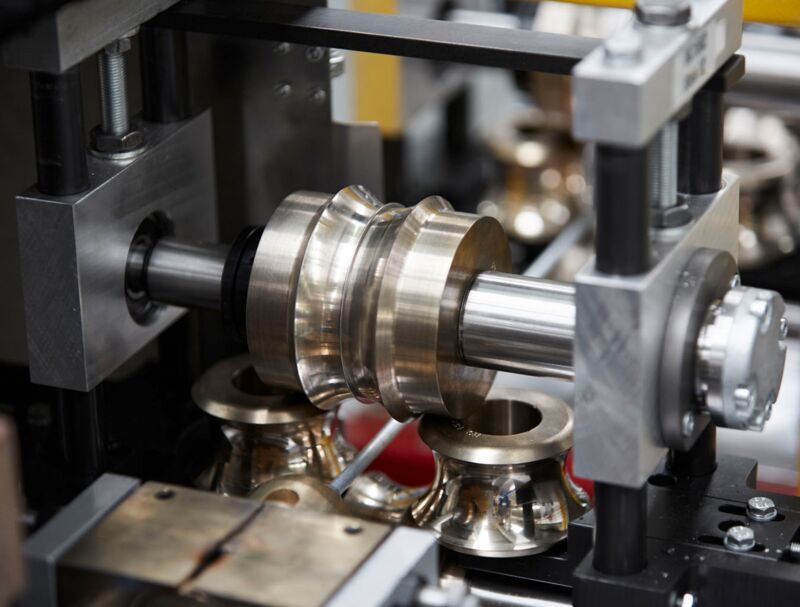

Pipe forming

Pipe forming is at the core of every composite pipe system. The method developed by us ensures that the produced pipe has minimal strain and minimal work hardening. At the end of pipe forming, the strip edges are precisely positioned as the pipe is transferred to the welding station. This is a further important prerequisite for fault-free welding. In addition to this, pipes that have been produced on DREISTERN roll forming systems, are better for working with because their deformability is better than that of pipes produced with other forming methods. This results in tighter radii during pipe installation. The deformability is of particular importance for fitting systems where the pipe ends are flared.

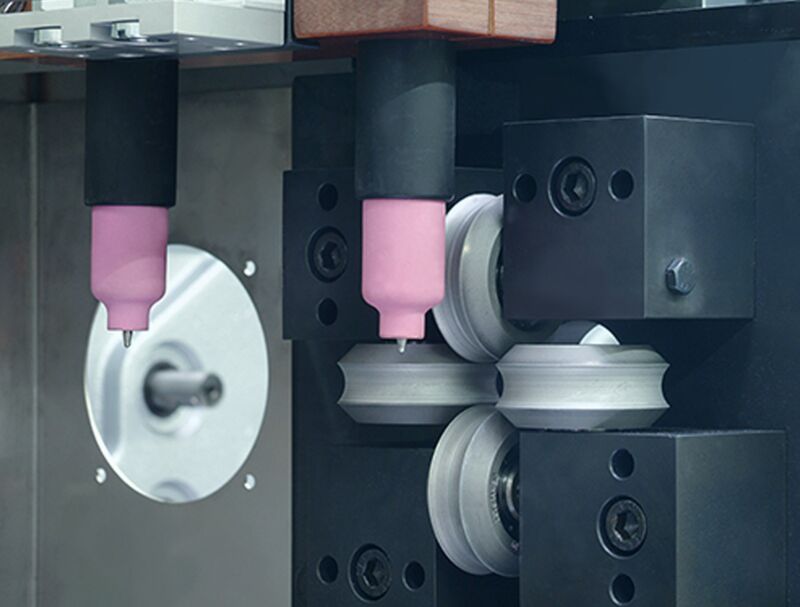

Welding station

We have many years experience of TIG welding and in the laser welding of composite pipes. In our own welding machine laboratory we are constantly optimising the welding process on your behalf in conjunction with the materials specialists of the aluminium suppliers and welding experts of the suppliers of the welding power sources and the welding lasers. The result is that our roll forming systems deliver perfect welds for all types of aluminium suitable for the composite pipe. Thanks to an automatic electrode tracking system, TIG machines produce uniformly high-quality welded joints without any intervention from the operator.

Compacting station

The last, but far from unimportant station of our pipe welding system is the compacting station. It ensures a fixed bond between the aluminium pipes and the PE inner pipe and also ensures high adhesion coefficients.

Engineering of entire systems

We are your specialist for the engineering of complex systems and supply reliable and on-time turnkey systems. Modern project management methods ensure a trouble-free sequence for the entire project. Thanks to close contact with all leading extruder manufacturers, we can implement systems in any desired configuration.