Flexible and efficient process

for a wide range of products and requirements

Applications for roll forming technology in electrical installation are very varied: you will receive precisely the correct roll forming machine for your products and requirements, combining inexpensive systems with high load bearing capacity, minimum material input, reliable operation and simple assembly.

Tried and tested technologies

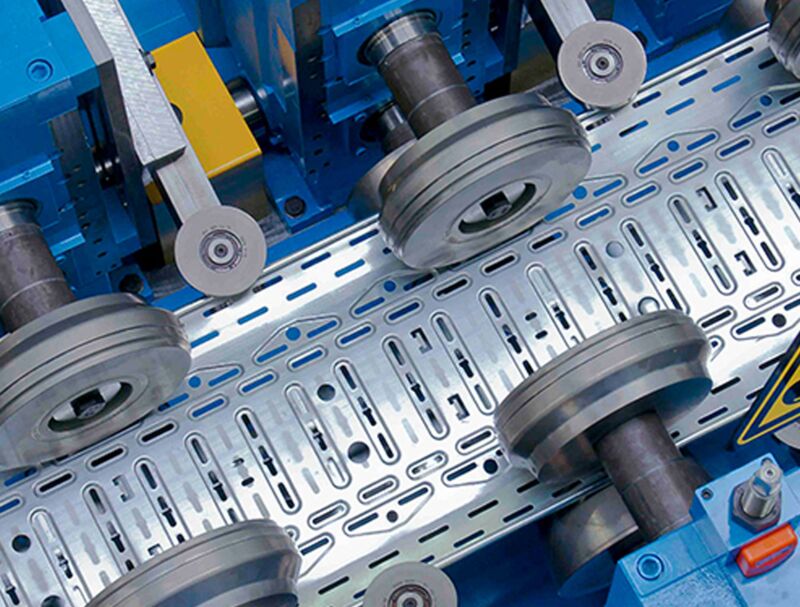

Cable trays, lid profiles for cable trays, adapters, ladder profiles or beam profiles for cable ladders and mounting rails are just a few of the applications of roll forming technology for the electrical industry: with our roll forming systems, you will benefit from the most flexible and efficient production process for such products.

This process is based on our huge amount of experience in the area of roll forming technology for electrical installation: we combine our tried and tested technology with application-specific processes such as pre-punching using mechanical or hydraulic presses or press tools, roller stamping of reinforcements, spot welding or clinching. This ensures the use of appropriate production processes for each product.

This is particularly impressive in production systems for cable trays and lids: we always supply you with the optimum solution, whether it be recognised screw systems or innovative and assembly-friendly plug-in systems. Adjustment of width and height is performed simply and quickly from the control console, the roll forming tools move automatically and precisely to the preselected dimension.

Professional roll forming machines

clearly presented

Form your own impressions of the precision and reliability of our roll forming machines: The video shows you clearly some of the advantages of our roll forming systems and processes.

Examples of roll forming machines

for cable ducts and electrical installation profiles

With our roll forming machines for the cable duct and electrical installation profile sector, you receive bespoke solutions for your individual products.

Strip preparation systems

Strip feeding systems are used for continuous supply of the roll forming system with the flat strip. They make an important contribution to the productivity of the overall system and the quality of the parts. Highly automated strip systems perform a complete coil change in 3 minutes, including welding of the strip ends. Precision-alignment systems and a low-stress strip feed into the downstream punching or roll forming machines provide the necessary conditions for the production of precision components with the narrowest of tolerances. Dependent on the nature of the requirements, use of the more cost-efficient standard system is also justified.

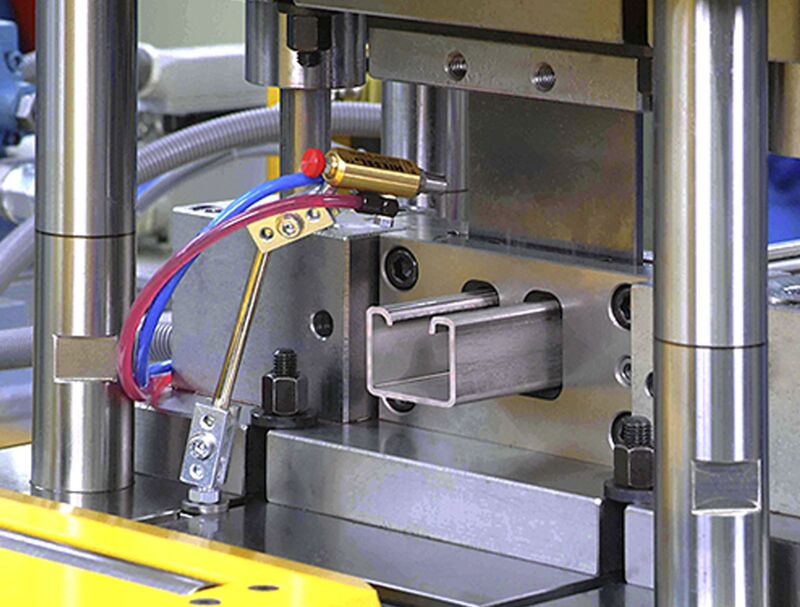

Roll forming machines in start-stop technology

We supply you with roll forming machines in start stop technology with a stationary cutting unit for inexpensive, conventional tool changing.

Roll forming machines with motorised cross adjustment

Roll forming machines with motorised cross adjustment offer you quick and continuous adjustment of the profile width and height at the press of a button, optionally with motorised adjustment axes for automatic adjustment of the material thickness. The standard versions are suitable for belt widths of up to 1,200 millimetres and belt thicknesses of up to 3.0 millimetres