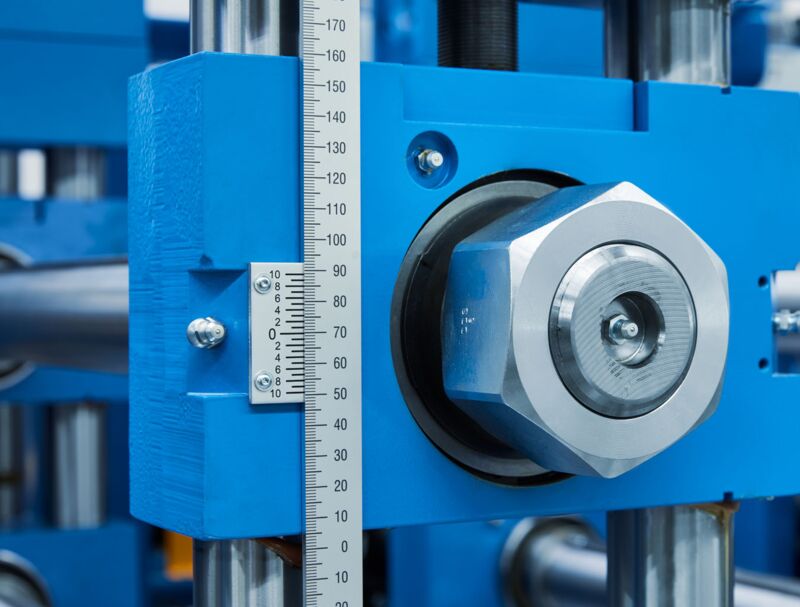

Running and guide rails

for highly automated shelving systems

Our diverse production concepts for running and guide rails will offer you enormous advantages. These include high productivity through extremely short set-up times and minimal material consumption through unrivalled low scrap rates. Your roll forming machine amortised itself in a short time and produces your products economically from day one on.

We can satisfy increased requirements

Profiles for semi or fully automated shelving systems have to withstand dynamic loads in addition to static. A high stiffness of the shelf supports is crucial. In addition, profiles such as running and guide rails require significantly higher accuracy in terms of dimension and tolerance. Deviations, for example at the rail ends, must be kept within very narrow limits.

Our goal is customers satisfaction

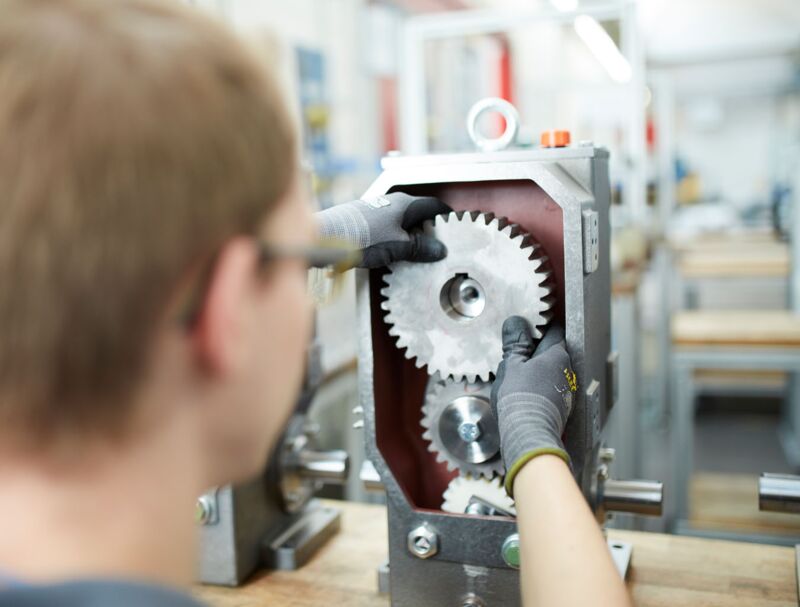

Checking the producibility of new profile shapes and engineering the appropriate roll forming tools is part of our dayly business. The experience from 10,000 roll forming tools flows into the design of your new roll forming tool. The result is checked by simulation. The testing of your roll forming tool gives you the security of immediate readiness for production. This also gives your customers the security of an optimally functioning and automated storage system. We have already been able to prove this in numerous projects. Let us know your requirements - we have the solutions.

Roll forming machines

Options

- Modular chained roll forming systems for load-optimised profile cross-sections.

- Automatic nesting and stacking systems

- Welding systems for head parts

- Continuous operation with flying cut-off machine

- Start-Stop technology with inexpensive stationary cut-off device.