Ideal solutions

for complex processes

Perfect cut-off machines combined with optimum cut-off processes.

Cut-off machines must fulfil a wide range of technical requirements: our experts prepare individual solutions for you. This applies also for the selection of the cut-off process (sawing, shearing, punching or special cut-off process) as well as for important implementation details of the cut-off machine such as adjustment options or the profile or tube clamping equipment.

Many years’ experience

The speed of your cut-off machine must keep up with the roll forming speed, possibly profiles are also transferred to downstream processes. As far as possible these complex processes must closely match the usually tight specifications of costs per cut. No standard machine can achieve this, therefore a multitude of technical solutions are required.

Our engineers in the area of cut-off machines are aware of this and only choose one of the many possible solutions when they have found the best for you. Their task is made easier by a wide range of proven modules, which are available to us thanks to our many years of experience in cut-off machines.

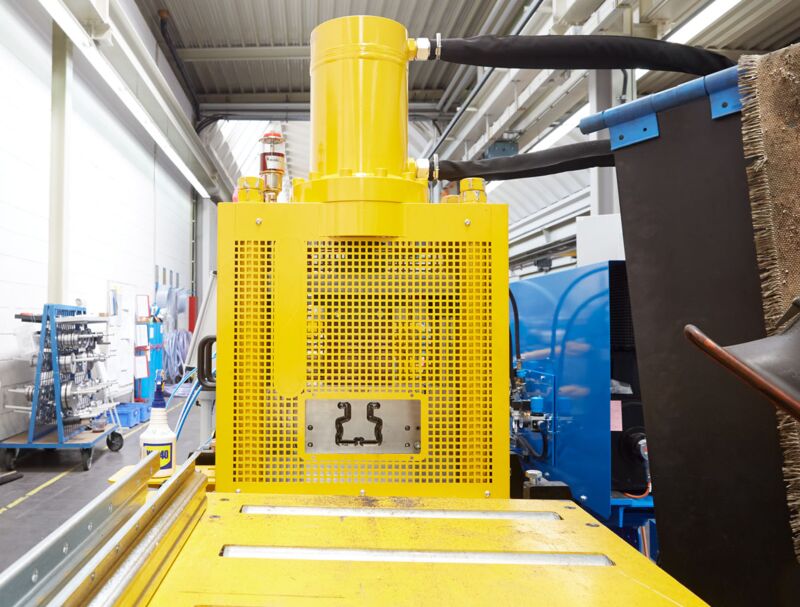

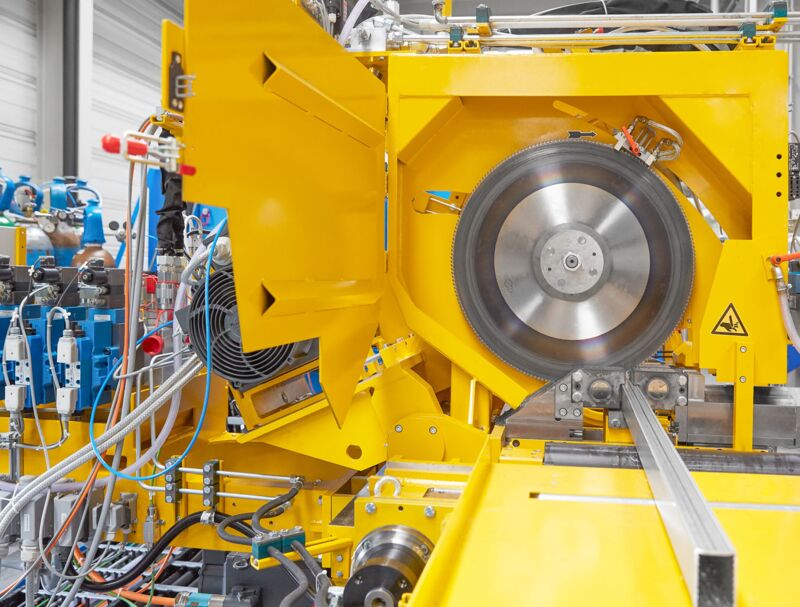

MKSmulti series

for effective cut-off sawing

The MKSmulti series allows you to smoothly integrate flexible cut-off sawing into your roll forming processes. You can also obtain our MKS 340, 650, 1063, 1071 and 2080 saws as autonomous solutions. Within your roll forming processes the MKSmulti series are optimally suited for our multifunctional roll forming machines, for flying or stationary cut-off machines and for autonomous, standalone metal circular saws.

Professional roll forming machines

clearly presented

Form your own impressions of the precision and reliability of our roll forming machines: The video clearly illustrates some of the advantages of our roll forming systems and processes.