Reduced material consumption

thanks to absolutely low scrap rates

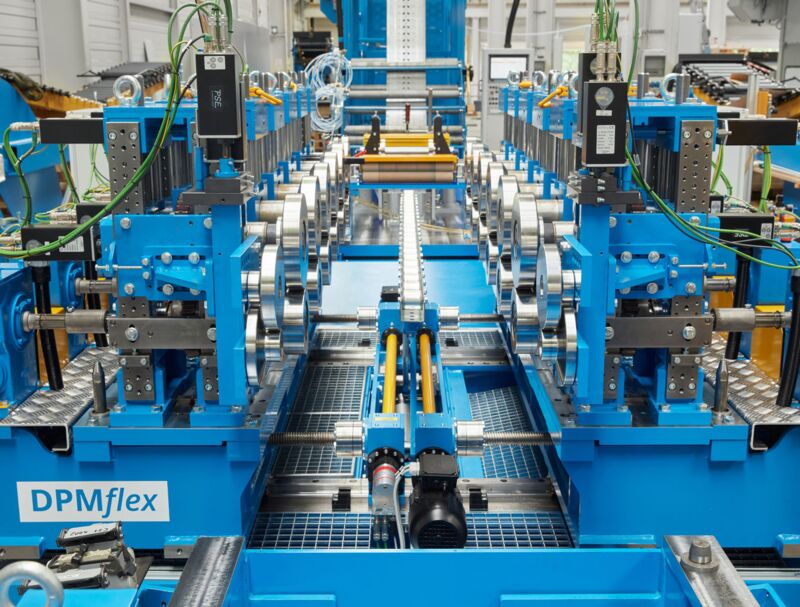

Our production concepts for beams and box beams provide you with lots of advantages. These include high productivity due to short setup times and minimum material consumption due to unrivalled low scrap rates. This ensure that your roll forming machines pay for themselves in the shortest possible times.

Optimum concepts developed for you

With our modular machine systems we can prepare the best roll forming system concept for your application and requirement. A two-stage forming system, based on a double roll forming machine is a highly flexible solution for single profile variants with different heights and widths. With modern fast tool change systems, you can setup all special forms for wood floors, metal lower shelves, grating shelves or tyre supports simply and without problems.

Our innovative double roll forming machines are also perfectly suited to double case profiles. Together with a flying cut-off system a production speed of 80 metres per minute is achieved. You can set the desired profile height at the touch of a button and without any roll change. Only the coil change and changing of the cut-off tool must be performed manually, although automated solutions are also available here too.

For a chained system with automated profile nesting and welding on of the hooking lugs, use of our proven Start-Stop®-System is recommended. In this way, the activities of the individual processing stations can be optimally matched to each other.

Roll forming machines

Options

- Modular chained roll forming systems for load-optimised profile cross-sections.

- Automatic nesting and stacking systems

- Welding systems for head parts

- Continuous operation with flying cut-off machine

- Start-Stop technology with inexpensive stationary cut-off device.